Difference between revisions of "Microduino-Module Motor"

From Microduino Wiki

(Created page with "{{Language|Microduino-Motor}} {| style="width: 800px;" |- | 400px|thumb|right|Microduino-A4982 Microduino-Motor is a motor driver control m...") |

|||

| Line 5: | Line 5: | ||

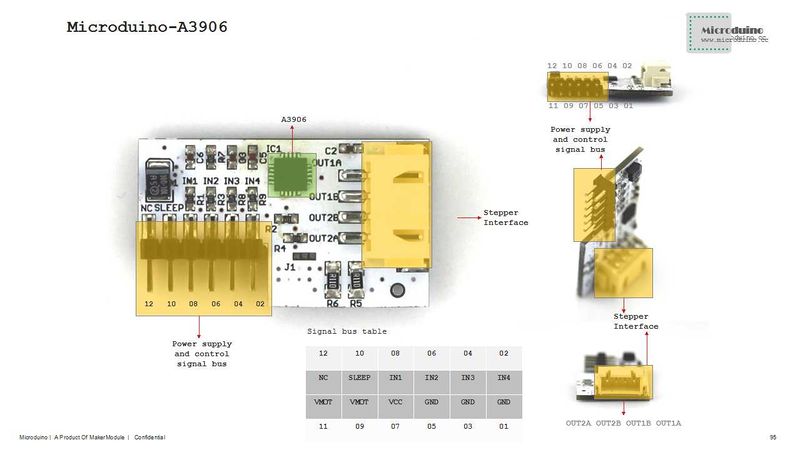

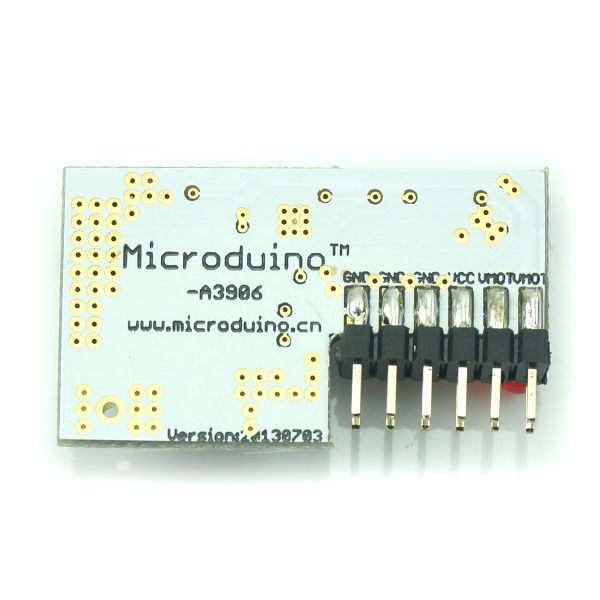

[[File:Microduino-a3906-rect.jpg|400px|thumb|right|Microduino-A4982]] | [[File:Microduino-a3906-rect.jpg|400px|thumb|right|Microduino-A4982]] | ||

| − | Microduino-Motor is a motor | + | Microduino-Motor is a motor drive controller with the PWM control function. It can be used to control dual full bridge low voltage stepper motor, single or dual DC motor, widely applied in smart car and robot control. |

| − | |||

| Line 13: | Line 12: | ||

==Feature== | ==Feature== | ||

*Internal PWM current limit control | *Internal PWM current limit control | ||

| − | *Synchronous rectifier | + | *Synchronous rectifier, capable of reducing power consumption |

*Under-voltage lockout | *Under-voltage lockout | ||

*Low RDS(on)output | *Low RDS(on)output | ||

*Dc motor braking mode | *Dc motor braking mode | ||

*Sleep function | *Sleep function | ||

| − | * | + | *Overcurrent protection |

| − | * | + | *Overheating Shutdown |

| − | *size | + | *Small size |

==Specification== | ==Specification== | ||

*20 pins | *20 pins | ||

*4 mm×4mm×0.75mm size | *4 mm×4mm×0.75mm size | ||

| − | *QFN package and | + | *With QFN package and naked pads for enhanced cooling |

*100% Matte tin plated pin | *100% Matte tin plated pin | ||

| Line 36: | Line 35: | ||

! rowspan="1" |Microduino Motor Pin||Microduino Pin||Function | ! rowspan="1" |Microduino Motor Pin||Microduino Pin||Function | ||

|- | |- | ||

| − | | SLEEP||Microduino IO port||Sleep | + | | SLEEP||Microduino IO port||Sleep logical input, low active |

|- | |- | ||

| IN1||Microduino IO port||Control input | | IN1||Microduino IO port||Control input | ||

| Line 50: | Line 49: | ||

| VCC||VCC||power to A3906 and Microduino | | VCC||VCC||power to A3906 and Microduino | ||

|- | |- | ||

| − | | GND||GND||Common | + | | GND||GND||Common Ground |

|} | |} | ||

| Line 61: | Line 60: | ||

==Development== | ==Development== | ||

| − | ===DC motor | + | ===DC motor wiring=== |

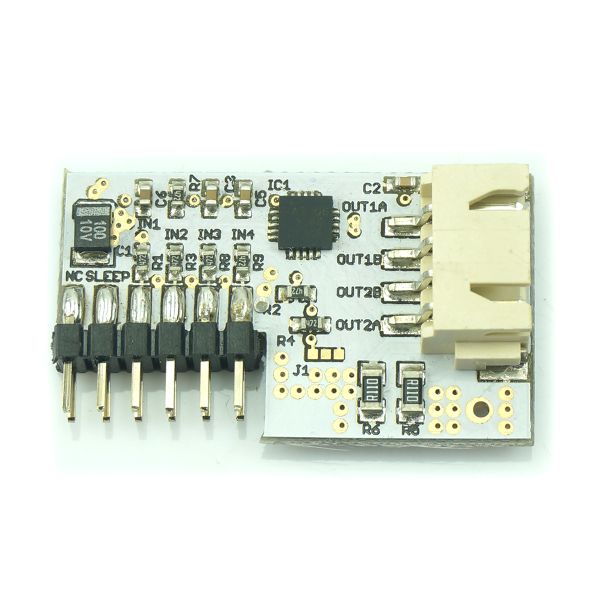

| − | Connect one DC motor to OUT1A,OUT1B, the other | + | Connect one DC motor to OUT1A,OUT1B, the other to OUT2A,OUT2B. |

====DC motor control mode==== | ====DC motor control mode==== | ||

| Line 79: | Line 78: | ||

|} | |} | ||

| − | ===Step motor | + | ===Step motor wiring=== |

*Connect step motor to Microduino Motor module: | *Connect step motor to Microduino Motor module: | ||

| − | ** | + | **The four-wire two-phase step motor has two sets of coil A and B. Each group of coil's resistance is very small, only a few ohm. |

| − | A and B group | + | A and B group are absolute insulated and disconnected. Just use a multimeter to measure, the one connected belongs to one group. |

| − | ** | + | **After identifying the A and B group, just connect one group to (OUT1A, OUT1B), the other to (OUT2A, OUT2B). |

====Step motor control mode==== | ====Step motor control mode==== | ||

| Line 115: | Line 114: | ||

Test program:'''[[File:Program Test A3906.zip]]''' | Test program:'''[[File:Program Test A3906.zip]]''' | ||

| − | ===A3906 | + | ===A3906 contorls two DB motors=== |

*Use Microduino core and Microduino A3906's control function; | *Use Microduino core and Microduino A3906's control function; | ||

| − | *Prepared hardware: Microduino | + | *Prepared hardware: Microduino FT232R,Microduino Core, Microduino Motor and two DC motors as well as a power supply(2.5~9V); |

| − | *Prepared software: Microduino | + | *Prepared software: Microduino test program(Arduino part) and Arduino IDE(version 1.0 and higher); |

| − | *Start Arduino IED,open the Microduino test program, | + | *Start Arduino IED,open the Microduino test program, choose "Microduino Core (Atmega328P@16M,5V)" and download directly; |

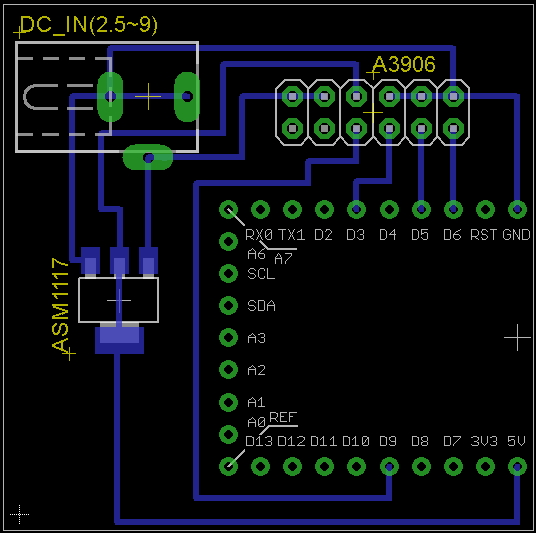

| − | Microduino core and Microduino Motor | + | How to make a pegboard with Microduino core and Microduino Motor connected: |

| − | *Set up the circuit on pegboard as | + | *Set up the circuit on pegboard as follows (blue line at the bottom) |

| Line 127: | Line 126: | ||

*Microduino Motor drive DC motor test: | *Microduino Motor drive DC motor test: | ||

| − | **Connect 5V or 9V power, motor | + | **Connect 5V or 9V power, the motor don't rotate initially: |

**Start Arduino IED serial monitor | **Start Arduino IED serial monitor | ||

***Input 0000, enter, two motors don't rotate | ***Input 0000, enter, two motors don't rotate | ||

| − | ***Input 0101, enter, Two motors forward | + | ***Input 0101, enter, Two motors rotate forward |

| − | ***Input 0110, enter, one motor forward | + | ***Input 0110, enter, one motor rotates forward and the other backward |

| − | ***Input 1001, enter, one motor backward | + | ***Input 1001, enter, one motor rotates backward and the other forward |

| − | ***Input 1010, enter, two motors backward | + | ***Input 1010, enter, two motors rotate backward |

***Input 1111, enter, two motors stop | ***Input 1111, enter, two motors stop | ||

Revision as of 09:13, 31 July 2014

| Language: | English • 中文 |

|---|

|

Microduino-Motor is a motor drive controller with the PWM control function. It can be used to control dual full bridge low voltage stepper motor, single or dual DC motor, widely applied in smart car and robot control.

ContentsFeature

Specification

Electrical specifications

Pin Description

DocumentDriver chip:A3906 File:A3906-Datasheet.pdf DevelopmentDC motor wiringConnect one DC motor to OUT1A,OUT1B, the other to OUT2A,OUT2B. DC motor control mode

Step motor wiring

A and B group are absolute insulated and disconnected. Just use a multimeter to measure, the one connected belongs to one group.

Step motor control mode

ApplicationProgram downloadTest program:File:Program Test A3906.zip A3906 contorls two DB motors

How to make a pegboard with Microduino core and Microduino Motor connected:

BugHistoryPicturesVideo |