Lesson 10--The first pegboard experiments (using electric iron)

| Language: | English • 中文 |

|---|

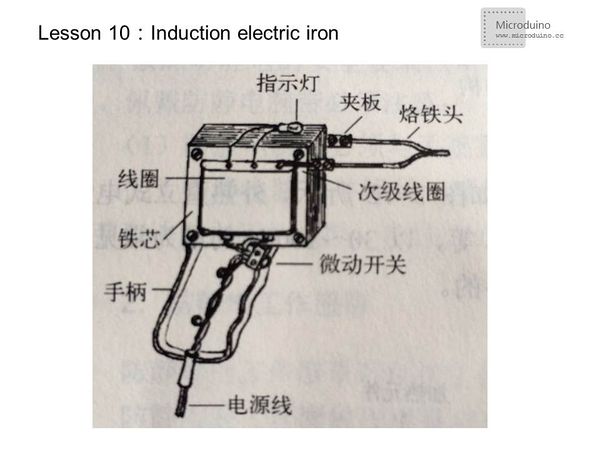

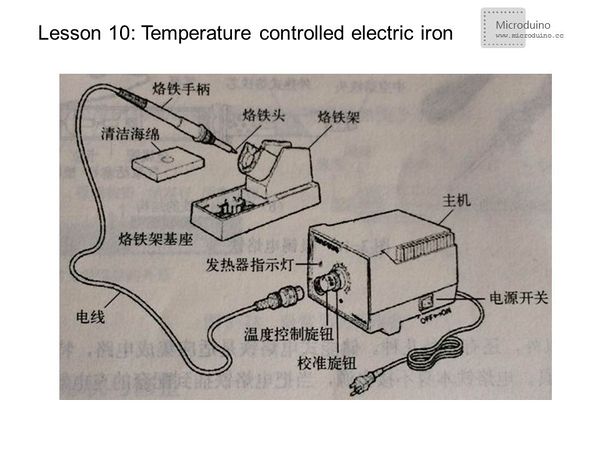

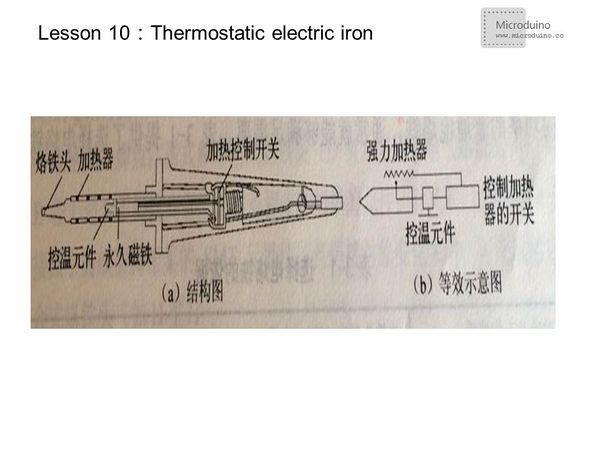

Contents[hide]ObjectiveIn Previous experiment, we always used breadboard to build circuit, but maybe you want to do the circuit by using the Pegboard, so this lesson will show you how to use the electric iron, and some of the problems of welding. Electric iron classificationInduction electric ironInduction electric iron, also called speed thermoelectric iron, commonly known as the torch. Actually it is a transformer. Its secondary winding only has one tune,therefore the current is large, and reach the welding temperature quickly, generally a few seconds can be. Temperature controlled electric ironTemperature controlled electric iron use the temperature sensor to detect the tip temperature, then amplifier the sensor output signal by a amplification to control the electric power supply circuit, so as to achieve temperature control. Thermostatic electric ironWelding head is equipped with a ferromagnetic sensor, the magnetic disappeared when the temperature reaches a certain point.Using this feature as a magnetic control switch to control the heating element on and off, so as to control the solder iron temperature.

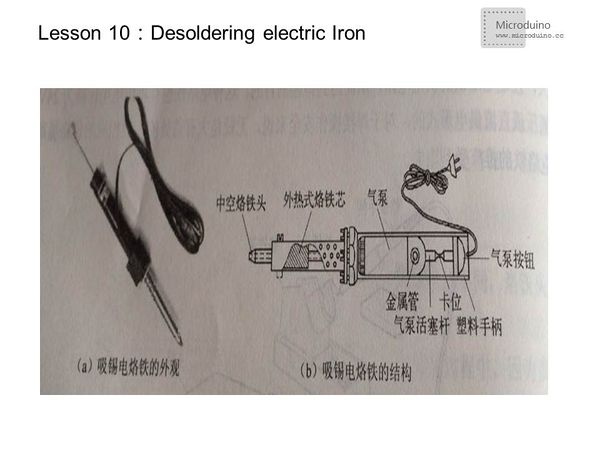

Desoldering electric IronIn the maintenance of electronic products, often need to remove certain components and parts, then use desoldering electric Iron can easily sucked the solder from the printed circuit board, so weldment separates from the printed circuit board, and then you can easily the inspection and replacement. When using desoldering electric Iron, press the pump button, compressed rubber bag, aligned with the hollow tip solder to heat. Until the solder melts when releasing the pump, solder was sucked inside tip; then remove the tip, press the pump button again, the solder is extruded. Choose the electric iron

The basic steps of the welding operation

From stem 3 to step5, maybe need 1~2s. Video |