Difference between revisions of "Microduino-Shield Robot"

From Microduino Wiki

(Created page with "{{Language|Microduino-Robot/zh}} {| style="width: 800px;" 400px|thumb|right|Microduino- Robot Microduino-ROBOT, as a robot control board,...") |

|||

| Line 4: | Line 4: | ||

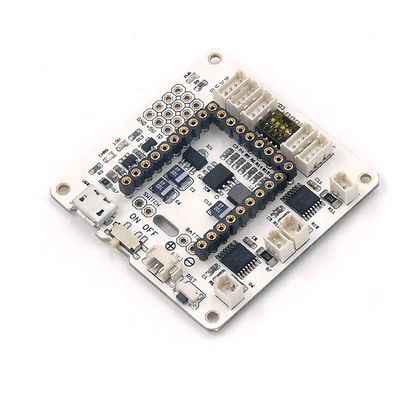

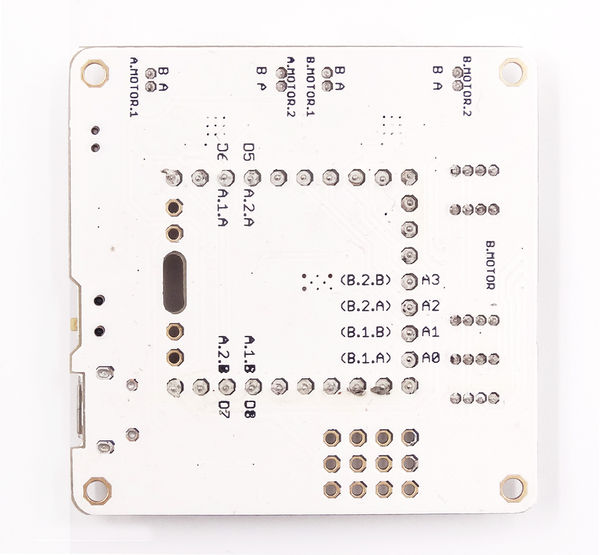

[[File: Microduino-Robot-rect.jpg|400px|thumb|right|Microduino- Robot]] | [[File: Microduino-Robot-rect.jpg|400px|thumb|right|Microduino- Robot]] | ||

| − | Microduino- | + | Microduino-Robot, as a robot control board, is used together with [[Microduino-Core+]], [[Microduino-Motor]] and [[Microduino-Stepper]]. With the onboard sensor interface, it enables users to introduce various sensors and achieve more functions. |

|- | |- | ||

| | | | ||

| Line 10: | Line 10: | ||

==Feature== | ==Feature== | ||

| − | *Two motor | + | *Two motor driver interfaces, capable of driving two stepping motors or four DC motors. |

*Rich sensor interfaces, easy for extension. | *Rich sensor interfaces, easy for extension. | ||

*5V and 3.3V battery management. | *5V and 3.3V battery management. | ||

| − | *Upin27 base board | + | *Upin27 base board to connect more Microduino modules. |

*Small size: 46.99mm*40.64mm | *Small size: 46.99mm*40.64mm | ||

==Specification== | ==Specification== | ||

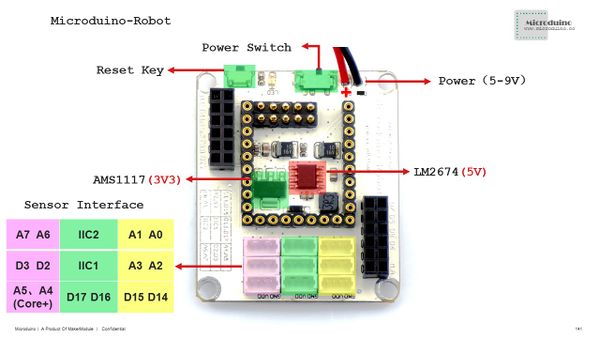

| − | *Electrical | + | *Electrical Specification |

**5V stabilivolt: Adopt LM2674 voltage reduction scheme. | **5V stabilivolt: Adopt LM2674 voltage reduction scheme. | ||

**3.3V stabilivolt: AMS1117 voltage reduction scheme. | **3.3V stabilivolt: AMS1117 voltage reduction scheme. | ||

**Please make sure power source within 5V-9V. | **Please make sure power source within 5V-9V. | ||

**Power switch | **Power switch | ||

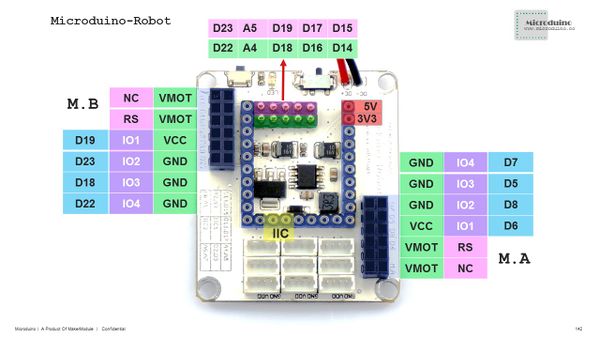

| − | *Motor | + | *Motor driver |

**M.A:D7,D5,D8,D6(suitable for Core and PWM speed adjustment) | **M.A:D7,D5,D8,D6(suitable for Core and PWM speed adjustment) | ||

**M.B:D19,D23,D18,D22(suitable for Core+ and PWM speed adjustment) | **M.B:D19,D23,D18,D22(suitable for Core+ and PWM speed adjustment) | ||

Revision as of 05:42, 29 January 2016

| Language: | English • 中文 |

|---|

|

ContentsFeature

Specification

Document

Development

Program examples: //=========M.A=============//

int mic_left_A = 7;

int mic_right_A = 5;

int mic_head_A = 8;

int mic_back_A = 6;

//=========M.B=============//

/*

int mic_left_B = 22;

int mic_right_B =18;

int mic_head_B = 23;

int mic_back_B = 19;

*/

void setup() {

pinMode(mic_left_A,OUTPUT);

pinMode(mic_right_A,OUTPUT);

pinMode(mic_head_A,OUTPUT);

pinMode(mic_back_A,OUTPUT);

}

void loop() {

head();

delay(1500);

back();

delay(1500);

left();

delay(1500);

right();

delay(1500);

}

void head()

{

digitalWrite(mic_left_A,LOW);

digitalWrite(mic_right_A,HIGH);

digitalWrite(mic_head_A,HIGH);

digitalWrite(mic_back_A,LOW);

}

void left()

{

digitalWrite(mic_left_A,HIGH);

digitalWrite(mic_right_A,LOW);

digitalWrite(mic_head_A,HIGH);

digitalWrite(mic_back_A,LOW );

}

void right()

{

digitalWrite(mic_left_A,LOW);

digitalWrite(mic_right_A,HIGH);

digitalWrite(mic_head_A,LOW);

digitalWrite(mic_back_A,HIGH);

}

void back()

{

digitalWrite(mic_left_A,HIGH);

digitalWrite(mic_right_A,LOW);

digitalWrite(mic_head_A,LOW);

digitalWrite(mic_back_A,HIGH);

}

void stoop()

{

digitalWrite(mic_left_A,LOW);

digitalWrite(mic_right_A,LOW);

digitalWrite(mic_head_A,LOW);

digitalWrite(mic_back_A,LOW);

}

Program example: #include <AccelStepper.h>

const int ENPin_A =8 ; // the number of the LED pin

const int ENPin_B =23 ; // the number of the LED pin

int motorSpeed = 9600; //maximum steps per second (about 3rps / at 16 microsteps)

int motorAccel = 80000; //steps/second/second to accelerate

int motorDirPin_A = 5; //digital pin 5

int motorStepPin_A = 7; //digital pin 7

int motorDirPin_B = 18; //digital pin 5

int motorStepPin_B = 22; //digital pin 7

//set up the accelStepper intance

//the "1" tells it we are using a driver

AccelStepper stepper_A(1, motorStepPin_A, motorDirPin_A);

AccelStepper stepper_B(1, motorStepPin_B, motorDirPin_B);

void setup(){

pinMode(ENPin_A, OUTPUT);

pinMode(ENPin_B, OUTPUT);

stepper_A.setMaxSpeed(motorSpeed);

stepper_A.setSpeed(motorSpeed);

stepper_A.setAcceleration(motorAccel);

stepper_A.moveTo(3200); //move 32000 steps (should be 10 rev)

stepper_B.setMaxSpeed(motorSpeed);

stepper_B.setSpeed(motorSpeed);

stepper_B.setAcceleration(motorAccel);

stepper_B.moveTo(3200); //move 32000 steps (should be 10 rev)

}

void loop(){

digitalWrite(ENPin_A, LOW);

digitalWrite(ENPin_B, LOW);

//if stepper is at desired location

if (stepper_A.distanceToGo() == 0){

//go the other way the same amount of steps

//so if current position is 400 steps out, go position -400

stepper_A.moveTo(-stepper_A.currentPosition());

}

//these must be called as often as possible to ensure smooth operation

//any delay will cause jerky motion

stepper_A.run();

if (stepper_B.distanceToGo() == 0){

//go the other way the same amount of steps

//so if current position is 400 steps out, go position -400

stepper_B.moveTo(-stepper_B.currentPosition());

}

//these must be called as often as possible to ensure smooth operation

//any delay will cause jerky motion

stepper_B.run();

}ApplicationMicroduino-Joypad Self-balance Robot KitBOXZ_mini RobotPurchaseHistoryPictures

Video |